Choosing the right flange is crucial for ensuring the reliability, safety, and efficiency of piping systems. Here is a comprehensive guide to help you make the right selection:

1. Types of Flanges

Flanges are categorized based on their design and application. The most common types include:

- Weld Neck Flange (WN)

- Characteristics: Long tapered hub for stress distribution, suitable for high-pressure and high-temperature applications.

- Applications: Oil & gas pipelines, power plants.

- Slip-On Flange (SO)

- Characteristics: Easy installation with double angle welding, lower initial cost.

- Applications: Low-pressure systems, non-critical applications.

- Socket Weld Flange (SW)

- Characteristics: Suitable for small-diameter, high-pressure piping, provides leak-proof joints.

- Applications: Chemical processing, hydraulic systems.

- Threaded Flange (TH)

- Characteristics: No welding required, suitable for low-pressure systems or explosive environments.

- Applications: Compressed air systems, water treatment plants.

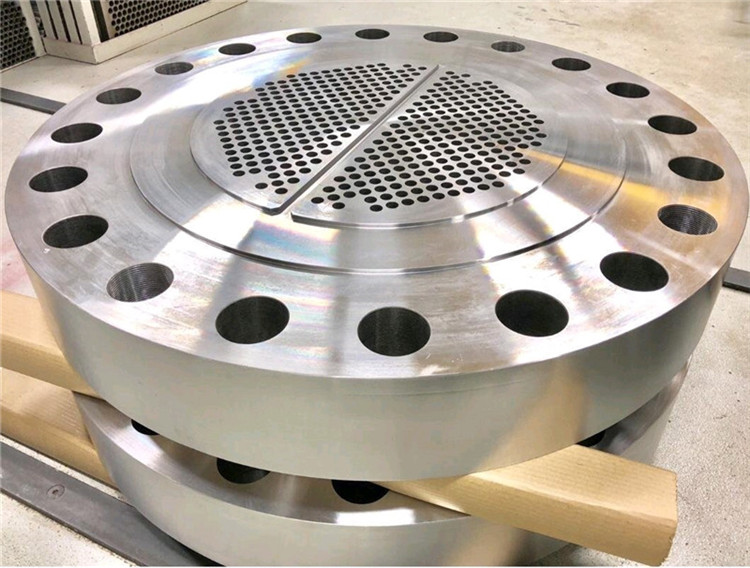

- Blind Flange (BL)

- Characteristics: Used to seal off pipe ends or vessel openings, ideal for pressure testing.

- Applications: Maintenance work, future expansion points.

- Lap Joint Flange (LJ)

- Characteristics: Used with stub ends, allows for rotation, easy dismantling.

- Applications: Systems requiring frequent inspection.

2. Key Considerations for Flange Selection

When selecting a flange, several factors must be evaluated to ensure compatibility and performance:

- Operating Pressure and Temperature

- Ensure the flange meets the system’s pressure and temperature requirements.

- Material Compatibility

- Choose materials that resist corrosion and meet the demands of the fluid being transported. Common materials include carbon steel, stainless steel, and alloy steel.

- Installation Method

- Decide whether welding or threading is more suitable for your application.

- Corrosion Resistance

- Select materials or coatings that can withstand corrosive environments.

- Industry Standards

- Adhere to relevant standards such as ASME B16.5 (ANSI), DIN, JIS, or IBR.

- Ease of Assembly and Disassembly

- Consider the frequency of maintenance and the ease of installation.

- Cost

- Evaluate the total cost of ownership, including installation and maintenance expenses.

3. Pressure Ratings and Flange Classes

Flanges are classified based on their pressure ratings, which include Class 150, 300, 600, 900, 1500, and 2500. The selection depends on the operating conditions of the system.

4. Additional Tips

- Consult with Experts: Always consult with a flange manufacturer or supplier to ensure compliance with industry standards.

- Measure Accurately: Ensure the flange size matches the pipe dimensions.

- Test Quality: Verify the flange’s quality and performance before installation.