Flanges are essential components in piping systems, and their surface treatment methods play a crucial role in ensuring their performance and durability. Here are some common surface treatment methods for flanges:

Hot-dip galvanizing: This method involves immersing the flange in molten zinc. The zinc forms a protective coating that prevents corrosion. It is highly effective in harsh environments and provides long-term protection.

Painting: Flanges can be coated with various types of paint, such as epoxy or polyurethane. These coatings protect against corrosion and can also provide a decorative finish. The choice of paint depends on the environment and the required level of protection.

Electroplating: This process uses an electric current to deposit a thin layer of metal, such as nickel or chromium, onto the flange surface. Electroplating enhances the surface hardness and corrosion resistance, making it suitable for applications requiring high wear resistance.

Bluing: This is a chemical process that forms a thin oxide layer on the surface of the flange. Bluing provides a certain level of corrosion resistance and has an aesthetic appeal. It is commonly used for small flanges and components in less corrosive environments.

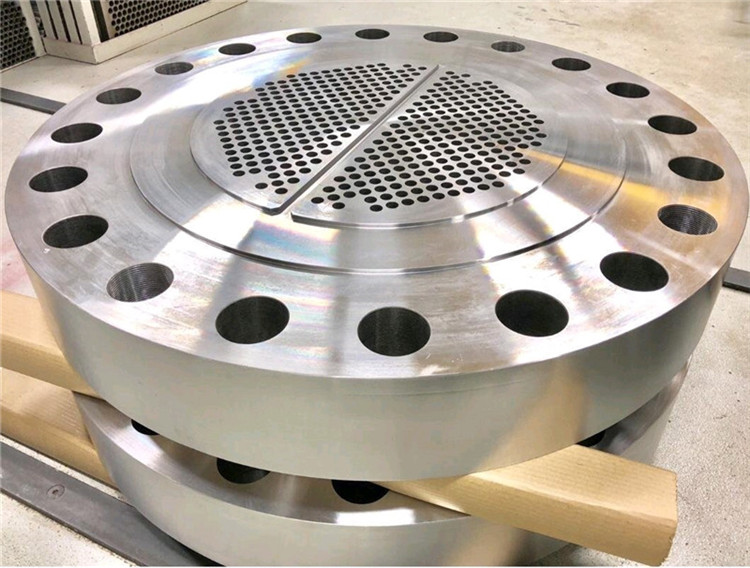

Mechanical surface treatments: These include grinding and polishing. Grinding is used to remove surface imperfections and achieve a smooth finish. Polishing further enhances the surface appearance and can improve corrosion resistance by reducing surface roughness.