Flange standards vary significantly between American, European, and national standards, with key differences in measurement systems, pressure ratings, bolt patterns, and material specifications.

Measurement Systems

- American Standards: Use the imperial system (inches, PSI) for dimensions and pressure ratings.

- European Standards: Utilize the metric system (millimeters, bar) for measurements and pressure classifications.

- National Standards: In countries like China, the metric system is also commonly used, aligning more closely with European practices.

Pressure Ratings

- American Standards: Pressure is rated in classes (e.g., Class 150, 300, 600) based on PSI.

- European Standards: Pressure ratings are designated by PN (Pressure Nominal) values (e.g., PN6, PN10, PN16) measured in bar.

- National Standards: Many countries use PN ratings similar to Europe, but specific classes may vary based on local industry requirements.

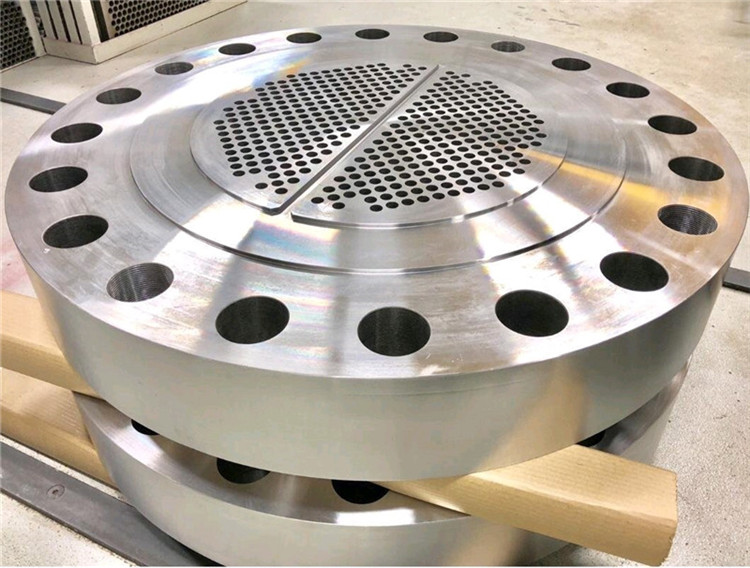

Bolt Patterns and Dimensions

- American Standards: Bolt hole patterns and dimensions are based on imperial units, with specific configurations for each pressure class.

- European Standards: Bolt patterns are metric-based, often leading to incompatibility with American flanges even if the nominal sizes appear similar.

- National Standards: Bolt patterns may vary by country, but generally follow metric standards similar to Europe.

Material Specifications

- American Standards: Materials are often specified using ASTM designations (e.g., A105, A182) and may include carbon steel, stainless steel, and alloy steel.

- European Standards: Materials are designated using European numbering systems (e.g., 1.0432, 1.4301) and include similar material types but with different specifications.

- National Standards: Material specifications can differ based on local availability and industry practices, though common materials like stainless steel are widely used.

Application and Regional Use

- American Standards: Predominantly used in the U.S., Canada, and some Latin American countries, especially in industries like oil & gas and power generation.

- European Standards: Widely adopted in Europe, Asia, and global maritime applications, particularly in process plants, pharmaceutical, and food industries.

- National Standards: Reflect local industry needs and regulatory requirements, with some countries adopting international standards for compatibility.